Our customers often ask us how to apply plasters in showers. Can decorative plasters such as Venetian plaster, Tadelakt, or microcement be applied to shower walls? The answer is a resounding yes! If you’ve ever dreamed of a bathroom free from the tedious chores of scraping mould or dirt from the grout between tiles, then plaster finishes might be the solution you’re looking for. The application of plasters to showers represents a sophisticated challenge in plaster finishing, but it comes with the promise of stunning and long-lasting results. Read on to learn how to apply plasters in showers, and to transform your ordinary bathroom into a luxurious, low-maintenance sanctuary. In this guide, we’ll explore the detailed methods to achieve flawless and enduring plaster finishes within your shower, ensuring that beauty meets durability in one of the most demanding environments of your home.

Applying natural lime-based plasters like Venetian plaster inside a shower can transform a standard bathroom into a spa-like sanctuary. These materials are a healthy, eco-friendly solution to create a luxurious, minimal feel. However, due to daily exposure to water and low air circulation, shower walls are prone to developing wet marks and mould. Despite these challenges, our extensive experience with plaster application in showers has equipped us with robust solutions, which we are excited to share with you.

Choosing the correct type of plaster is crucial for shower applications. Always choose smooth plasters over coarse, textured ones. Indeed, smooth finishes do not retain organic residues that lead to mould growth. Here are some recommended options: Note that only Hydrocement can be applied to shower trays. If you choose a plaster other than Hydrocement, make sure you only apply to the shower walls, and not to the tray.

Red Tadelakt shower

Peach Marmorino Medium shower

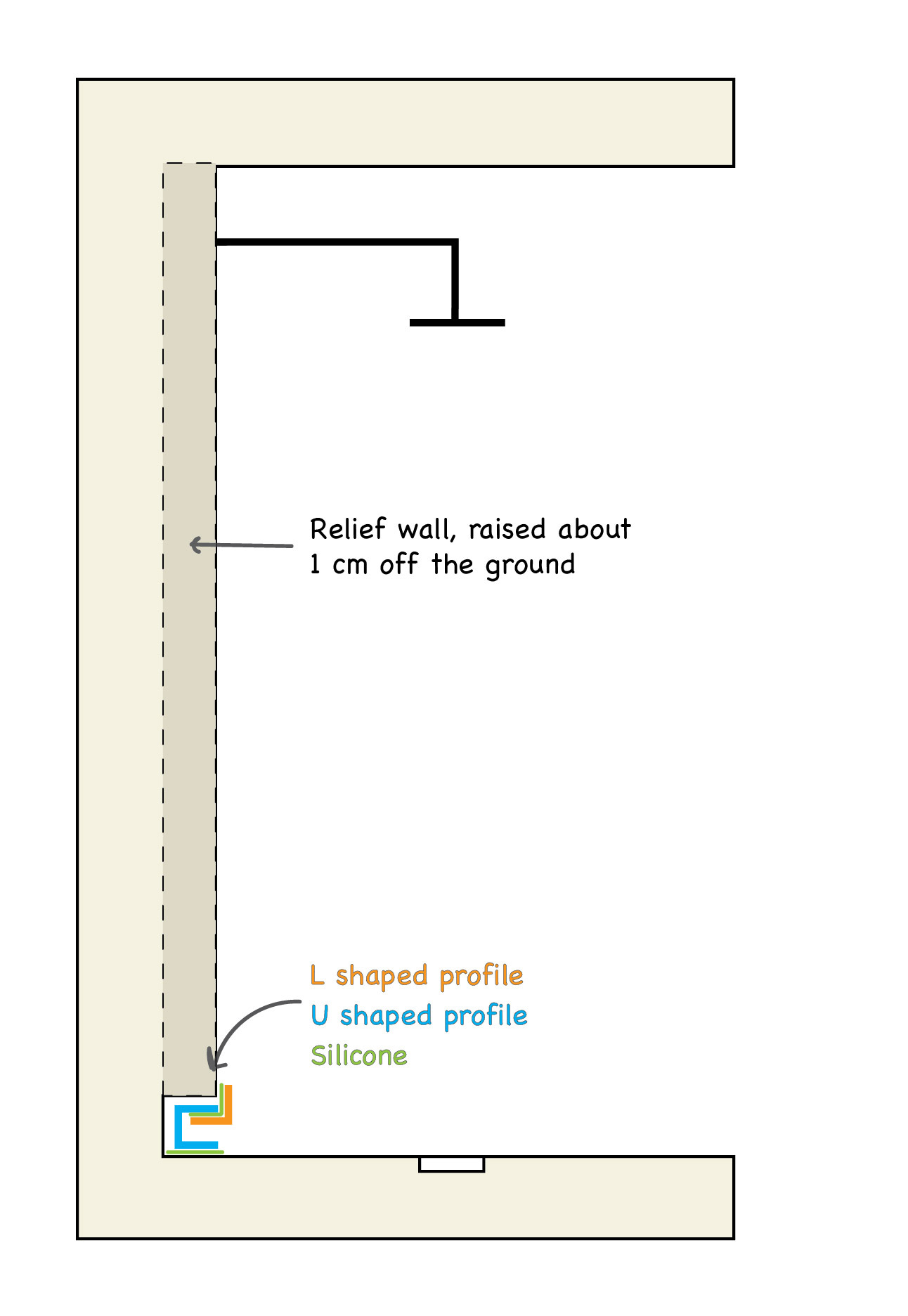

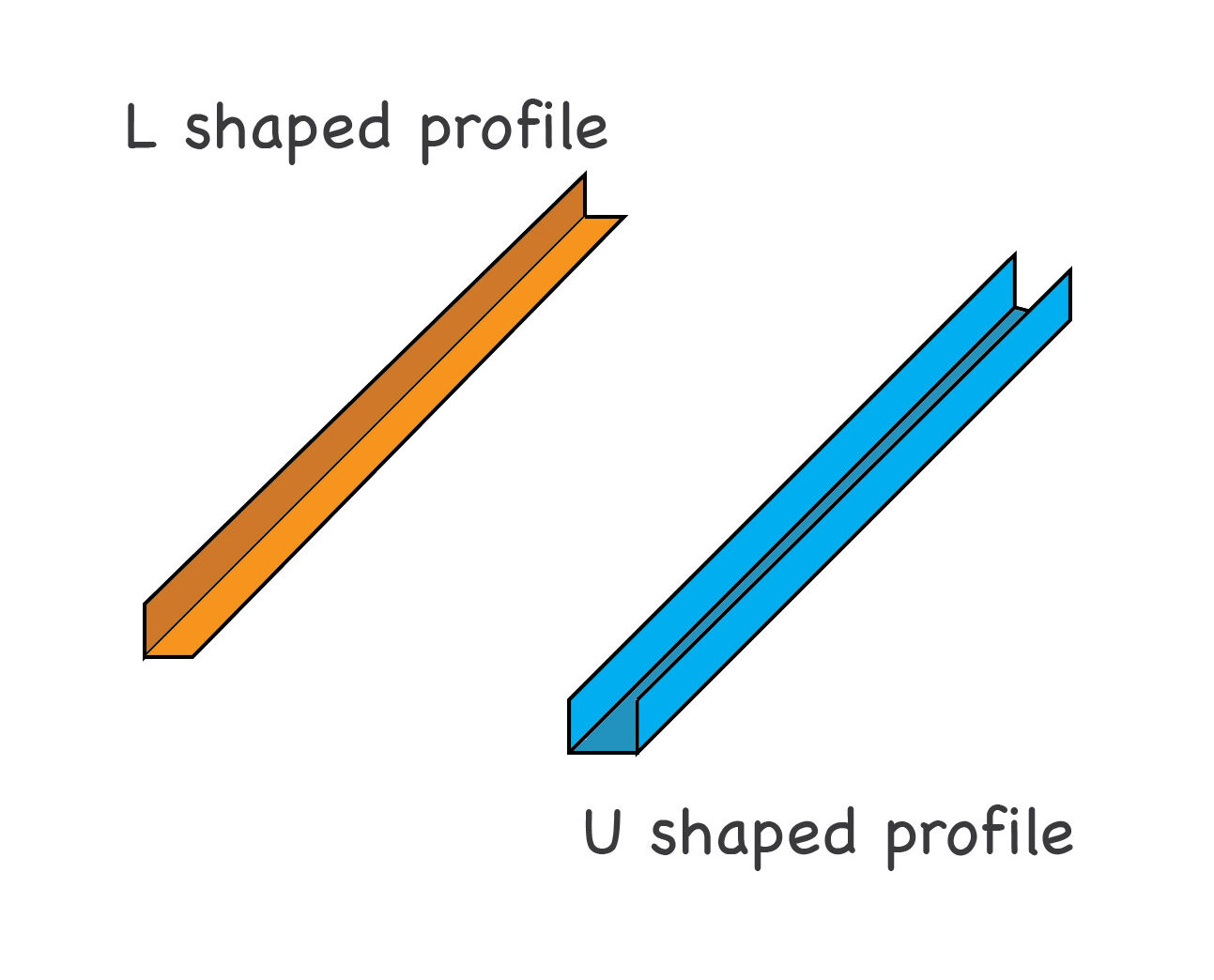

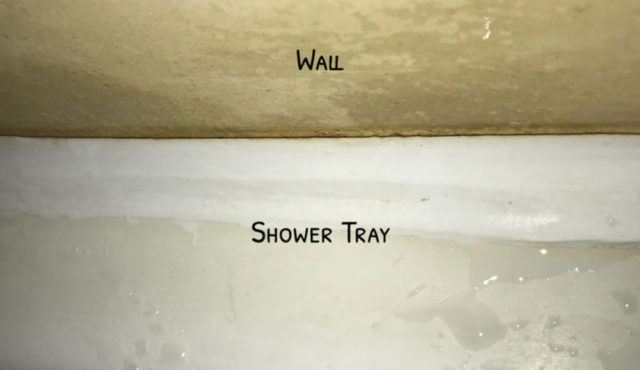

When applying plasters in showers, a crucial aspect to consider is the sealing between the wall and the shower tray. This area is particularly prone to the accumulation of damp and dirt. These can lead to severe wet and mould stains if not properly managed. Whether you’re renovating an old bathroom or working on a newly constructed one, creating a shadow gap at this junction is essential for maintaining the integrity and appearance of your plaster finish.

Video: How to create the shadow gap and apply the steel profiles

To ensure a durable finish when applying plaster to shower walls, it’s essential to prepare a substrate that is both resistant and flexible. Below, we detail the procedures for preparing two common types of shower wall surfaces: those covered with a waterproofing membrane and pre-existing tiled surfaces. In many regions, it is mandatory to cover shower walls with a waterproofing membrane. This, however, is typically designed for tiling and not for plaster finishes. These membranes are flexible, and the softness of the membrane can lead to cracks in the plaster. Procedure:

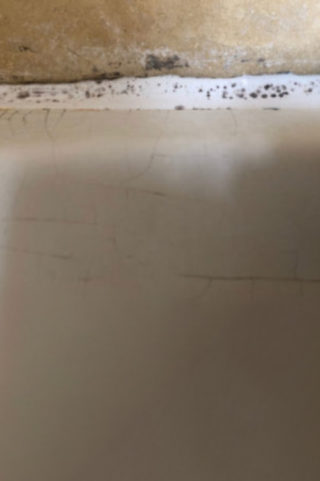

Mistake 1: Marmorino was applied directly over a waterproofing membrane. Cracks formed around the faucet handles, eventually occurring all along the walls.

If your project involves applying plaster over old tiles, creating a level and adhesive substrate is crucial. Procedure:

For walls that do not have existing tiles or waterproofing membranes: directly apply a Quartz Primer to create a suitable base for the plaster. The primer should provide enough adhesion to support the plaster finish. Once you have prepared your substrate, you can apply your chosen decorative plaster normally, whether it be Venetian Plaster, Tadelakt or Microcement.

Application of GLP between the gaps of very small tiles

After completing the decorative plaster application inside showers, proper waterproofing is critical to prevent the rapid appearance of moulds and permanent damage caused by moisture. This section will guide you on selecting the right waterproofing treatments. We’ll also explain how to protect vulnerable areas where water tends to dry slowly. Shower walls are susceptible to stains from prolonged dampness and moulds from organic deposits, like skin cells and soap residues. Corners and lower wall sections are particularly prone to these issues. For this reason, showers need very effective waterproofing treatments. Here is our recommended method:

Two particularly vulnerable areas in the shower require extra attention:

If you opt for a paraffin wax treatment to protect your plaster, it’s crucial to apply the silicone sealant before the paraffin. This is because silicone does not adhere well to surfaces treated with paraffin, leading to peeling and ineffective sealing. Check other common mistakes in the images below to learn how to apply plasters in showers correctly.

Mistake 2: a bad waterproofing led to permanent “wet effect” stains on the plaster

Mistake 3: a bad waterproofing led to the creation of mold around the handle ring and on the wall corners

Mistake 4: water has slipped into the handle ring and therefore into the substrate plaster, creating spots around the handle.

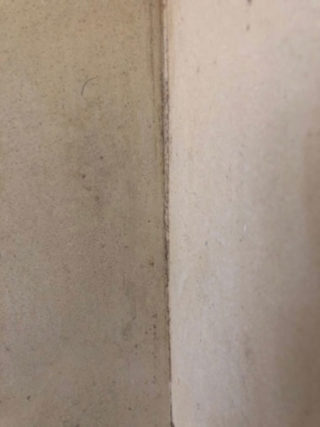

Mistake 5: damp and dirt accumulate in the sealing between the wall and the shower tray, originating mold stains.

Mistake 6: the silicone seal has peeled off because it was applied on top of the paraffin treatment

It was completed with Hydrocement, a shadow gap, and correct waterproofing. By following these comprehensive steps and tips, learning how to apply plasters in showers is easily within your reach, turning your bathroom into a stylish and mold-resistant area. Adopt these methods to guarantee that your shower walls remain both attractive and long-lasting.

How to Apply Venetian Plaster to Shower Walls

Applying Plasters in Showers: a Worthy Challenge

Step-by-Step Guide: How to Apply Plasters in Showers

Selecting the Right Decorative Plaster

Creating an Effective Shadow Gap in Showers

Step-by-Step Guide: Constructing a Shadow Gap

Last steps to completing the Shadow Gap:

Preparing a Substrate for Plaster Application in Showers

a. Applying Plaster Over a Waterproofing Membrane

b. Applying a Decorative Plasters Over Tiles

c. How to Apply Plasters in Showers Without Tiles or Membranes

Waterproofing Shower Surfaces and Critical Points

I. Choosing the Right Final Treatment for Your Plaster

II. Protecting Critical Areas: Tap and Shower Tray Seal

III. Common Mistakes

A successful application